Biomass is a renewable resource often considered in energy transition scenarios as a key option to decarbonise systems. However, operational difficulties related to resource supply chains could limit the long-term development of this energy.

The development of renewable energy is seen as an improvement for the global energy system due to limited fossil fuel resources, as well as to reduce the environmental problems resulting from the massive use of fossil fuels. In this context, the use of biomass and waste has become a sustainable solution for energy production. This allows the use of energy for transport, buildings, industry, agriculture, etc., encompassing a wide range of thermochemical, physicochemical and biochemical potentials. Energy from biomass can make a significant contribution to reducing greenhouse gas emissions, particularly in sectors that are difficult to decarbonise through electricity such as aviation, heavy transport and industry. But bioenergy, which is massively land-intensive, often results in substantial carbon emissions from land-use change and from the production, harvesting and transport of the resource to energy production sites. Moreover, bioenergy only expands with intensive use of large amounts of land, a resource that is inherently limited in supply and in competition with other needs such as food production, biodiversity preservation, among others. Finally, two other limitations hindering the increased use of biomass for energy production are the cost and complexity of its logistical operations. In the context of biomass energy use, what are the biomass-to-energy technologies and associated uses that relate to the supply chain issue?

1. Context, energy potential for biomass and issues

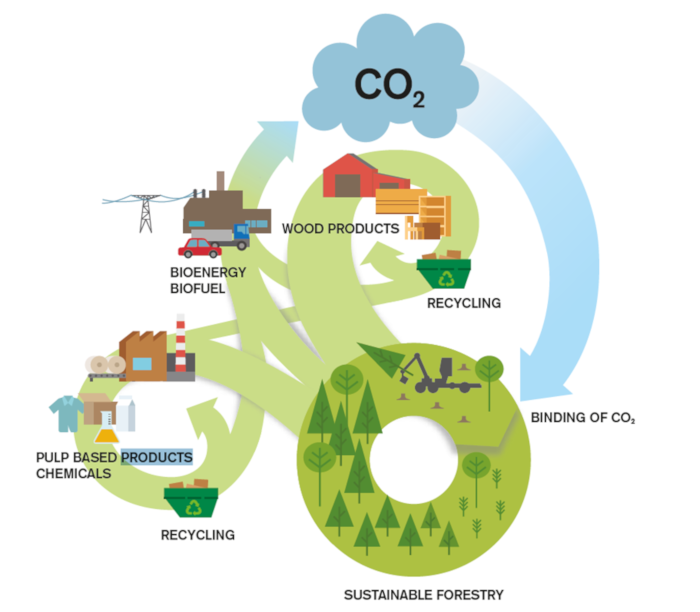

The term biomass includes vegetation, energy crops, as well as biosolids, animal, forest and agricultural residues, the organic fraction of municipal waste and certain types of industrial waste (Read: Biomass and energy: from primary resources to final energy products). Its attractiveness is due to its global availability, its energy conversion efficiency and its ability to be produced and consumed on a CO2 neutral basis. Indeed, it is considered that the carbon emitted during the combustion of biomass has been captured during its growth (Figure 1). [1]

Renewable energy sources play a central role in the current global context of greenhouse gas emission reduction strategies and the planned replacement of fossil fuels. Fossil fuels, oil, gas and coal, are the main sources of energy used in the world in 2020, up to 80%, and their distribution is concentrated in only a few countries, building a fragile energy supply, dependent and structuring geopolitical relations, with supply limits expected in the future (Read: Economics and Policy of Mineral Coal ; Natural Gas and Liquefied Natural Gas (LNG) Markets)

In 2020, bioenergy represents 9.5% of total primary energy supply and about 70% of renewable energy. Theoretically, the total contribution of bioenergy (theoretical potential of agricultural, forestry, animal and organic wastes) could amount to 1100 exajoules (EJ), three times the current world energy consumption of 410 EJ [2] (Read: Biomass and energy: from primary resources to final energy products). Numerous research studies document the current and potential role of biomass in the future global energy supply, which could provide up to 50% of the world’s energy needs [3][4]. This reinforces the important potential of biomass in the future global energy supply.

Biomass supply requirements, quality and quantity, can differ considerably depending on the type of energy demand, the energy production technology, the end use of the energy produced and the cost effectiveness and complexity of the logistical operations. To this end, the structuring of the supply chain carries the challenge of developing effective policies adapted to an uncertain environment and subject to local, regional and interregional conditions and constraints, such as infrastructure, geographical distribution of collection areas, regulatory and techno-economic environment and competition among consumers. The growing demand for biomass and the increasing complexity of supply systems, often spread over several locations and actors, therefore underline the need for comprehensive approaches to biomass and waste supply chain management. At the heart of these developments are several questions: what are the characteristics of biomass supply chains that differentiate them from conventional networks? What strategic, tactical and operational decisions should be made to develop the biomass and waste supply chain? What types of policies are needed to implement bioenergy systems? What are the advanced energy conversion technologies that a potential energy producer should invest in?

2. Biomass Energy Production Technologies

A thorough understanding of the technologies available for biomass energy production is an essential part of the strategic design of any biomass supply chain network. The conversion of waste biomass and organic substrates into energy encompasses a wide range of different biomass types and sources, conversion technologies, and end uses.

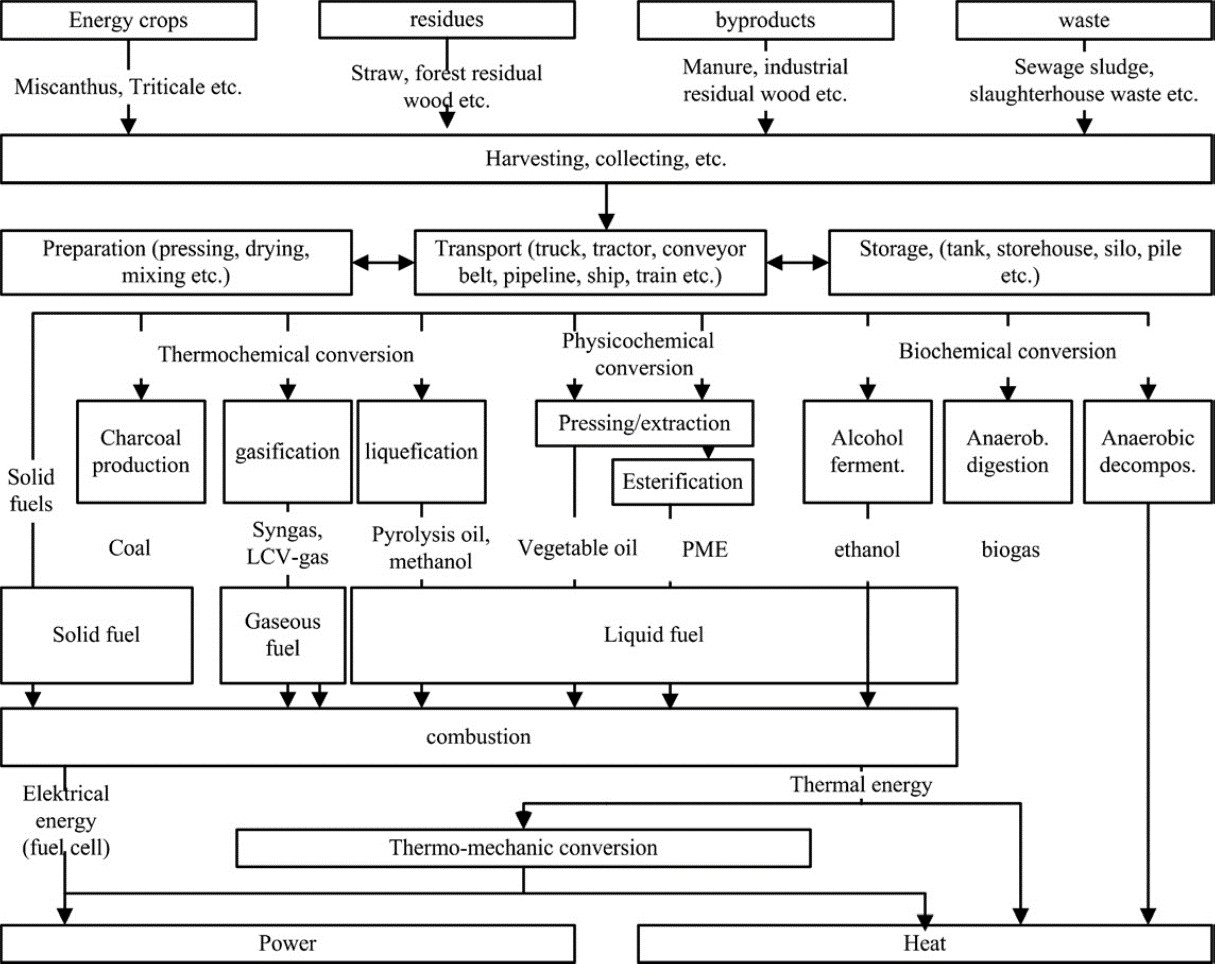

Biomass can be converted to energy products via three broad categories of processes: thermochemical, biochemical, and physicochemical (Figure 2). Thermochemical conversion processes transform biomass into solid, liquid or gaseous fuel [5]. Biochemical conversion is based on biological processes. The most developed options are alcohol produced from biomass containing sugar or starch (e.g. beet), and biogas production from crops or organic waste (e.g. animal manure). Finally, physico-chemical conversion processes can provide liquid fuels (e.g. biodiesel) by physical (e.g. pressing) and chemical (e.g. trans-esterification) means from energy crops.

It is important to have a strategic view of the ramifications and various parameters of all these technology options on biomass supply chains. Indeed, this would facilitate the identification of optimal configurations for bioenergy supply systems and network construction. The main characteristics of biomass energy processes are outlined below. These processes are described in more detail in the other articles mentioned in the text.

2.1. Thermochemical processes

Combustion is used on a wide range of products to convert the chemical energy stored in the biomass into heat, mechanical energy or electricity. Biomass combustion produces hot gases at temperatures around 800-1000°C. It is possible to burn any type of biomass, but in practice, combustion is only carried out for biomass with an intrinsic moisture content of less than 50%. Indeed, biomass with a high moisture content is better suited to biological conversion processes [7] (Read: Biomass and energy: from primary resources to final energy products).

Gasification is the conversion of biomass into fuel gas. The process is a partial oxidation at high temperature, typically in the range of 800 to 900°C [8] (Read: Gasification). The syngas produced is a mixture of hydrogen, carbon monoxide and other gases (Read: Green Hydrogen Production). This low calorific gas produced can be burned directly or can be used as fuel for gas engines and gas turbines after purification. It can also be used as a raw material in the production of chemicals.

Pyrolysis is the conversion of biomass into liquid, solid and gas. A thermal treatment between 200 and 1000°C produces mainly a liquid allowing the conversion with a yield up to 80%. This liquefaction process is the conversion of biomass into a stable liquid, which is then used as a hydrocarbon. This liquid can be used in engines and turbines and its use as a raw material for refineries can also be considered [9] (Read: Biomass and energy: from primary resources to final energy products).

2.2. Biochemical processes

Methanization is a technology based on the degradation of organic matter by micro-organisms, under controlled conditions and in the absence of oxygen, thus in an anaerobic environment (unlike composting which is an aerobic reaction). This degradation produces a solid, wet, rich in partially stabilized organic matter, called digestate. The process also produces biogas, a gaseous mixture saturated with water at the outlet of the digester and composed of approximately 50% to 70% methane (CH4), 20% to 50% carbon dioxide (CO2) and other gases (NH3, N2, H2S) in small quantities. Biogas has a net calorific value of 5 to 7 kWh/Nm3. This renewable energy can be used in combustible form for the production of electricity and heat, a fuel, or for injection into the natural gas network after purification. Anaerobic digestion or methanisation is therefore the direct conversion of organic matter into biogas, a mixture mainly of methane and carbon dioxide, with an energy content of about 20 to 40% of the lower heating value of the raw material (Read: Methanisation: from wastewater treatment to biogas injection into the network). It is a proven technology and also used to treat biological products and wastes waste with high moisture content, e.g. greater than 50% [10].

3. Biomass and waste supply chains

In this technological context, the biomass and waste supply chains play a major role in the structuring and technological development of the sector.

3.1 Structure

The structure of the global biomass market is changing quite dynamically. Biomass has been used in a “traditional” way for energy production (mainly thermal) in areas close to the production sites with inefficient devices such as open hearth combustion (Read: Energy for off-grid Africa: diagnosis ; Rural electrification in Sub-Saharan Africa ; What energy transitions in Sub-Saharan Africa?). Nevertheless, a “modern” use is emerging for energy producers who seek to improve the efficiency of biomass energy conversion. This involves the implementation of more efficient pre-treatments, processes and devices. In addition, there is a structuring of the biomass supply from several suppliers in order to develop a critical mass, centralized, necessary for the implementation of a larger energy production facility and therefore with scale effects on energy costs and yields. The increased complexity of this system dictates the need to develop supply chain planning and coordination methodologies as opposed to traditional resource management.

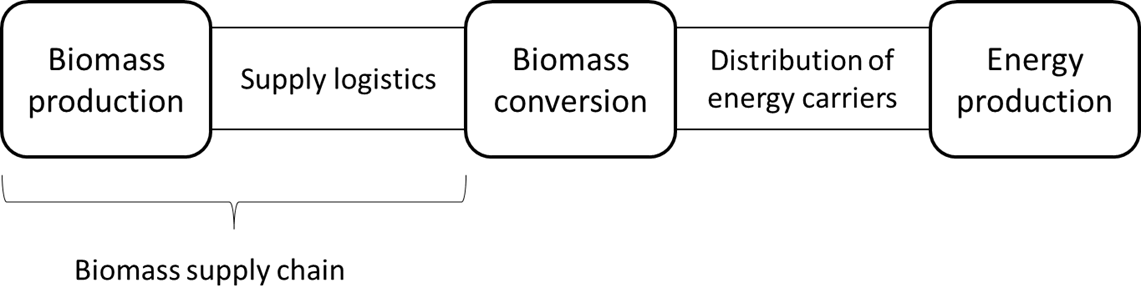

These residual biomass supply chains for energy production generally consist of four general system components: (i) biomass harvesting/gathering (from one or more sites) and pre-processing, (ii) storage (in one or more intermediate locations), (iii) transportation (using one or more steps) to feed the energy conversion (Figure 3).

These supply chains have several unique characteristics that differentiate them from traditional energy supply chains. Firstly, agricultural biomass is generally characterized by seasonal availability, resulting in the need to store large quantities of biomass for long periods of time. This results in a greater need for storage space, which leads to high storage costs for a linearized year-round operation. In addition, weather-related variability and competing uses of biomass waste in a competitive market must be taken into account when determining the flows of the material supply network. The complexity of biomass supply chains is heightened for perishable products, as this severely limits acceptable transportation times and storage duration for this type of resource. In addition, most forms of biomass tend to have a low energy density per unit mass compared to fossil fuels. This often makes handling, storage and transportation more expensive per unit of energy transported. In addition, these supply chains need to be robust and flexible enough to adapt to unpredictable market changes, as the demand for the energy produced depends on the type of conversion facility, and therefore the need, and the price of the resource.

3.2. Vectors for improvement

Several theoretical studies have included the installation of bioenergy conversion technologies in their models of the biomass supply chain. For example, the results of using three biomass-to-electricity conversion technologies, fluidized bed combustion with steam turbine, fluidized bed gasification with combined gas-steam cycle, and anaerobic digestion, conclude that 56-76% of the total operating costs of the system are due to the logistics of the biomass resource, highlighting the weight of this chain in the efficiency and profitability of the entire process [12]. There is therefore a great potential for improvement and cost reduction in this chain, as it is responsible for more than half the cost of the technology.

Existing systems in different parts of Europe have been used as practical case studies and as a basis for commercial scale demonstrations. The main obstacles identified are the biomass storage and the production phase for dedicated crops. Improvement levers may be increased efficiency in the harvesting and transport stages, with several possible pathways: densification of the resource after harvesting, possible thermal pre-treatment, reduction of transport costs on the basis of energy content, for example via packaging in bales or bundles that are sufficiently dense to make the exploitation of agricultural residues profitable, or the densification of lignocellulosic resources in the form of briquettes (Figures 4 and 5). We can also play on the reduction of the transport footprint by ensuring the local origin of the resource used, transported with low-polluting means (such as rail) and the development of cultivation systems allowing the staggering of the supply over the year, to limit the need for storage, and having a high productivity. All these efforts would reduce costs, energy consumption and greenhouse gas emissions [13].

4. Conclusion

Bioenergy already represents a significant share of the global energy mix but based on current trends and policies towards decarbonisation of energy systems, there is potential to increase this share over the coming decades. However, the use of biomass for energy, which provides both climate benefits and sustainable energy production, may be more limited than most models and scenarios predict.

The efficiency and competitiveness of resource supply chains are therefore key to the wider development of bioenergy. Innovative developments have been implemented with new harvesting methods (new harvesting machines for short rotation crops, new cutting head for herbaceous crops) and planning (computerised resource use planning system to monitor biomass flows and stocks in a supply chain). Other innovations are medium-term, but also have significant potential to reduce costs and improve the sustainability of these supply chains, such as knowledge of the benefits of crop associations and rotations, or improvements in thermochemical biomass pre-treatment processes [14].

Moreover, in addition to the technical and economic aspects, the use of biomass for energy is coherent if and only if this energy production does not create problems related to air, soil, water pollution or water scarcity, and ideally if it is equipped with a carbon capture device allowing to have not a low or zero carbon footprint but a negative one (Read: Carbon capture and storage).

Notes and references

Cover image. [Source: Didi43, CC BY-SA 4.0 <https://creativecommons.org/licenses/by-sa/4.0>, via Wikimedia Commons]

[1] IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. [Core Writing Team, R.K. Pachauri and L.A. Meyer (eds.)]. IPCC, Geneva, Switzerland, 151 pp, 2014.

[2] Mantulet G, 2020, The contribution of renewable gases to the decarbonisation of energy systems

[3] Parikka, M., 2014. Global biomass fuel resources. Biomass Bioenergy 27 (6), 613-620.

[4] Yamamoto, H., Fujino, J., Yamaji, K., 2011. Evaluation of bioenergy potential with a multi-regional global-land-use-and-energy model. Biomass Bioenergy 21 (3), 185-203.

[5] Balat, M., Kırtay, E., Balat, H., 2019. Main routes for the thermo-conversion of biomass into fuels and chemicals. Part 1: pyrolysis systems. Energy Convers. Manage. 50, 3147-3157.

[6] Kaltschmitt, M., Thrän, D., Smith, K., 2014. Renewable energy from biomass. Encyclopedia Phys. Sci. Technol. 203, 28.

[7] Velis, C.A., Longhurst, P.J., Drew, G.H., Smith, R., Pollard, S.J.T., 2019. Biodrying for mechanical-biological treatment of wastes: a review of process science and engineering. Bioresour. Technol. 100, 2747-2761.

[8] Cao, Y., Wang, Y., Riley, J.T., Pan, W.-P., 2006. A novel biomass air gasification process for producing tar-free higher heating value fuel gas. Fuel Process. Technol. 87, 343-353.

[9] Xu, C., Etcheverry, T., 2008. Hydro-liquefaction of woody biomass in sub- and supercritical ethanol with iron-based catalysts. Fuel 87, 335-345.

[10] Iakovou, E, et al, 2010, Waste biomass-to-energy supply chain management: A critical synthesis, Waste management 30, pp1860-1870

[11] Bambara, L, 2018, Analysis and optimization of sustainability of oilseed biofuel production systems in West Africa

[12] Caputo, A.C., Palumbo, M., Pelagagge, P.M., Scacchia, F., 2005. Economics of biomass energy utilization in combustion and gasification plants: effects of logistic variables. Biomass Bioenergy 28 (1), 35-51.

[13] Gold S., Seuring S., 2011. Supply chain and logistics issues of bio-energy production. Journal ofCleaner Production, 19, 32-42.

[14] Benoit, G, et al, How to optimize supply chains for biomass from energy crops. Innovations Agronomiques, INRA, 2017, 54, pp.23-29.